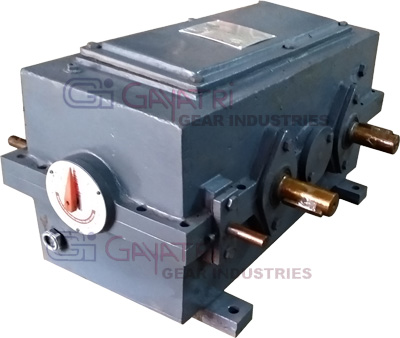

HERE IS THE P.I.V CHAIN DRIVE- POSITIVE POWER TRANSMISSION

YET INFINITELY VARIABLE – REALLY STEP-LESS SPEED CONTROL.

The sprockets of the P.I.V chain drive are two pairs of the cone- shaped radically – grooved wheels mounted on splined shafts.

The chain is made from unique links which contain packs of self – tooth – forming hardened steel slats. Each slat is free to move side wise and conform to the tooth shape of the paired sprockets. When the paired wheels are far apart the chain actually operates around a small diameter. When the wheels are close together the chain operates around a large diameter.

This principle – varying the driving and driven diameters – is the principle on which all variable speed control with positive power transmission.

Maximum Speed Setting

Minimum Speed Setting

Adjusts input shaft wheels close together to form a large driving diameter. This automatically separates output shaft wheels to form a small driven diameter.

Adjust input shaft wheels wide apart to form a small driving diameter.This automatically closes output shaft wheels to form a large driven diameter.

RATING OF BASIC P.I.V GEARS

OPERATING ADVANTAGES

Positive and exact – The P.I.V can’t slip. Because it has Chain Drive, the P.I.V can provide accurate speeds, infinitely variable within the range of each unit. This makes the P.I.V a unique variable speed transmission, particularly useful where delicate or sensitive operations are involved.

Long dependable life – Proper design and careful manufacture of parts, broad use of many alloy steels heat-treated for maximum strength and wear resistance, and automatic lubrication from a common reservoir, insure long life as attested by many P.I.V installation with over 25 years of service.

Low maintenance requirements – Maintenance is limited to maintaining correct chain tension and oil level.

An infinite number of speeds – Between maximum and minimum settings, can be easily obtained by simply turning the control screw while the P.I.V is operating. The Control screw may also be activated by many types of automatic controls.

Maximum speed setting – adjusts input shaft wheels close together to form a large driving diameter. This automatically separates output shaft wheels to form a small driven diameter.

Minimum speed setting – Adjust input shaft wheels wide apart to form a small driving diameter. This automatically closes output shaft wheels to form a large driven diameter.